Baldivis Trunk Sewer Main

The construction of this 755m gravity sewer trunk main was required to connect the Tuart Ridge subdivision’s sewer network to the existing Baldivis sewer infrastructure.

-

Client:

Okeland Pty Ltd

-

Location:

Baldivis Road, Baldivis WA

-

Construction Period:

Jan 08 – Oct 08

-

Key Elements:

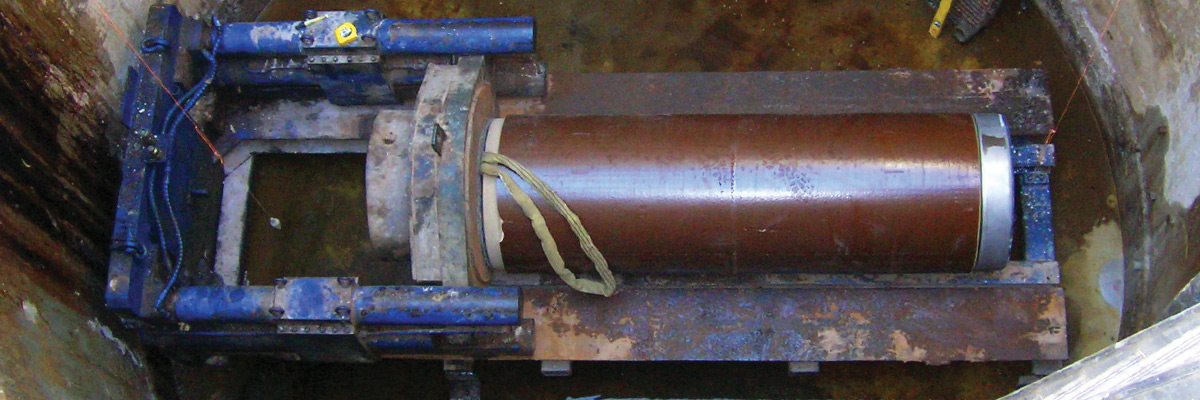

- Microtunneling

- Caisson construction

- Type 6 sewer MH construction

- Deep sewer installation

- Dewatering management

- Traffic management

Project overview

At the time, DM Civil were engaged to complete the Tuart Ridge subdivision. This, coupled with our trenchless technology capabilities, resulted in the client electing to award this contract to DM Civil, ensuring a seamless transition between internal subdivisional works and external head works.

The sewer alignment was within close proximity to natural wetlands and ran alongside a densely vegetated tramway reserve. This made the management of acid sulphate soils (ASS) and dewatering discharge extremely important.

The entire trunk main was constructed using trenchless techniques. 632m of DN500 and 123m of DN600 vitrified clay jacking pipes was installed with 7 Type 6 plastic lined access chambers. This was a challenging project for the Trenchless Technology Division with approximately half of the sewer being installed below the water table. In order to reduce the amount of dewatering required, sealed reinforced concrete caisson pits were constructed at each access chamber location to act as thrust and receival pits.

DM Civil was able to deliver 2 in-house capabilities – Land Development and Trenchless Technology – guaranteeing the client a streamlined construction approach to both the subdivision and trunk sewer main.

Significant achievements and benefits

DM Civil were able to mitigate project risks relating to environmental impact on local wetlands, excavation of ASS and dewatering. Furthermore, traffic flow along Baldivis Road was maintained. Overall, we were successful in reducing potential additional works and associated costs to the client.

A receival pit and access chamber needed to be constructed in the middle of Baldivis Road whilst still allowing for the large traffic flow in the area. A new roundabout was also being constructed at the same location. Timing of these works was critical and required a high degree of cooperation between the microtunneling and roadworks crews. With DM Civil able to carry out both the lead in sewer and internal subdivisional works, full control of the sequencing and timing of these works resulted in minimal impact to the local community and traffic flow.

The contract was originally awarded to DM Civil with only two sections of the sewer required to be installed by trenchless techniques. Our commitment to environmental management ensured that we investigated various issues with open cutting the remaining sections of sewer. We submitted an alternative proposal, which was accepted, to microtunnel the entire length of sewer to reduce the amount of dewatering required, ASS treatment and impact on existing vegetation.

Thrust and receival pits were constructed using 4.2m internal diameter concrete caissons. These were formed and poured onsite and sunk into position from the surface. This kept the impact on the existing vegetation to a minimum. These pits were fully sealed for the tunnelling rig to drill from and therefore, only minimal dewatering was required. This method limited the volume of soil to be excavated, reducing the amount of ASS and applicable treatment costs encountered.

DM Civil was able to construct the major lead in sewer in conjunction with the Tuart Ridge subdivisional works. The trunk main was successfully installed under roads and through an environmentally sensitive area, with very little impact on the community and environment.

Download the Baldivis Trunk Sewer Main project report